In any manufacturing process, maintaining high product quality is crucial. IIoT supports real-time monitoring and enables integration with Manufacturing Operations Management (MOM) and Manufacturing Execution Systems (MES). By linking IIoT data with ERP systems, manufacturers can monitor production quality continuously, detecting defects early and reducing reject rates. For instance, a medical device manufacturer recently implemented a real-time monitoring system with ERP integration, reducing reject rates from 30% to 2%.

Understanding the Impact of IIoT in Manufacturing

A pharmaceutical company recently leveraged IIoT and blockchain integration to track raw materials and finished products throughout its supply chain, securing product authenticity and increasing customer trust. IBM’s IIoT expert, Liza Morales, emphasized the strategic benefits, stating, “IIoT and blockchain together offer unmatched supply chain transparency, reinforcing compliance and reducing fraud risk.” This use of connected technologies is helping manufacturers respond to the growing consumer demand for transparency and accountability in supply chains.

Real-Time Data as the Driving Force

The IIoT enables manufacturing companies to connect physical assets—such as machinery and equipment—to the internet, where data exchange and real-time analytics help make informed decisions quickly. According to recent insights from Forbes contributor and IoT strategist, Sarah Cooper, “IIoT technology allows manufacturers to achieve previously unimaginable levels of efficiency by bridging the gap between physical and digital processes.” This integration provides manufacturers with unprecedented visibility into their shop floors, enabling them to employ predictive maintenance, enhance quality control, and achieve efficiencies tailored to their unique production environments.

By Randy Ferguson

Enhancing Operational Efficiency

2023 data from IDC confirms the impact of IIoT on quality control: “IIoT is not only reducing waste but also improving customer satisfaction by enabling consistent, high-quality production,” stated Andrew Neilson, a senior analyst at IDC. This real-time quality monitoring gives manufacturers the agility to identify and correct production inconsistencies before they escalate.

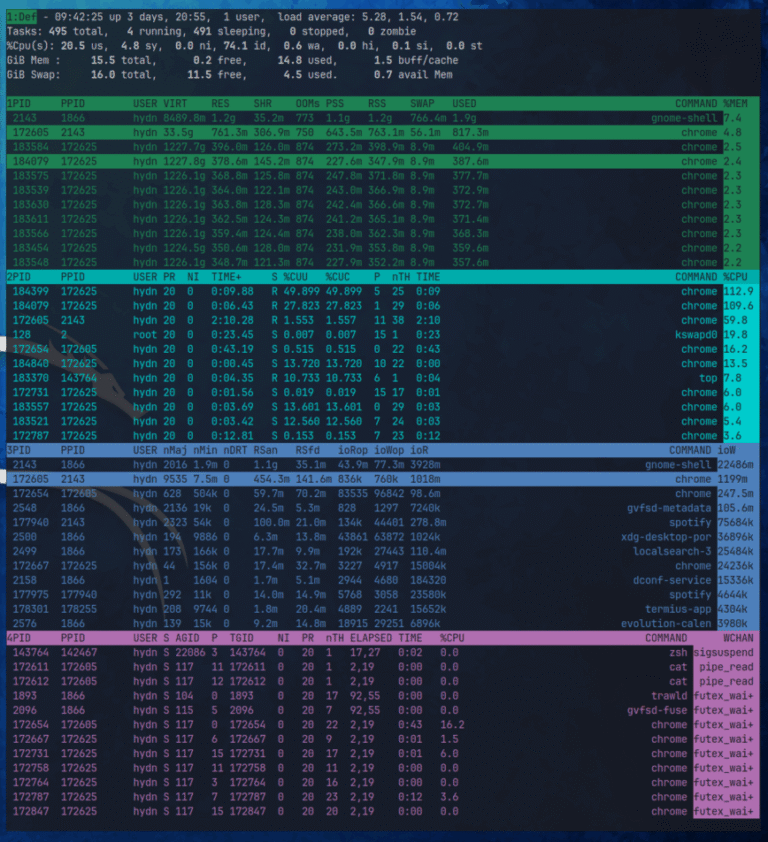

Implementing IIoT systems presents unique challenges, such as integrating with legacy infrastructure, managing large volumes of data, and ensuring cybersecurity. Scalable IIoT platforms that support diverse protocols and standards are critical. Additionally, edge computing, which enables local data processing, helps to manage data more effectively by reducing latency and bandwidth usage. Cybersecurity measures such as strong authentication and encryption are essential to protect sensitive manufacturing data.

Predictive Maintenance and Asset Management

IIoT’s influence extends beyond the manufacturing floor to the entire supply chain, providing end-to-end visibility that enhances coordination and efficiency. Tracking raw materials, work-in-progress, and finished products in real time enables companies to optimize stock levels, reduce buffer stock, and improve order accuracy. When combined with technologies like blockchain, IIoT further enhances supply chain transparency, ensuring product authenticity and lowering the risk of counterfeiting.

Real-time data analysis is the engine of IIoT’s transformative impact on manufacturing. By continuously monitoring equipment conditions and production processes, manufacturers can detect anomalies early, predict potential failures, and take corrective actions before minor issues escalate. “Real-time insights are no longer a luxury; they’re a necessity in staying competitive,” remarked Mike Kavis, Chief Cloud Architect at Deloitte, in a 2023 interview. He emphasized that “data-driven insights improve visibility across production lines, minimizing downtime and extending equipment longevity.”

Quality Control and Product Improvement

A consumer electronics manufacturer recently integrated IIoT solutions to monitor and optimize its production line. By analyzing real-time data, the company identified bottlenecks and streamlined its operations, achieving a 20% boost in production efficiency and a 10% reduction in material waste. Industry expert Brandon Gregg from Accenture commented, “IIoT-powered automation isn’t just about speed—it’s about sustainability, agility, and meeting the modern demand for responsible production.”

For example, an automotive parts manufacturer recently implemented an IIoT-based predictive maintenance system that monitored critical parameters such as vibration, temperature, and pressure. By detecting issues early, the company reduced unplanned downtime by 30% and increased the lifespan of its equipment by 15%. These operational improvements underscore the power of IIoT in optimizing maintenance and production schedules.

Transforming the Supply Chain with IIoT

Manufacturing Operations Management (MOM) and Manufacturing Execution Systems (MES) are critical in driving efficiency gains in modern manufacturing. MES provides real-time visibility into production, enabling manufacturers to track work-in-progress, monitor equipment status, and maintain adherence to production schedules. Meanwhile, MOM offers a holistic view of manufacturing operations, encompassing MES functionalities along with quality control, maintenance, and inventory management.

As Gartner’s 2023 insights suggest, “The successful implementation of IIoT starts with scalable pilot projects and stakeholder engagement.” Starting small allows companies to refine their strategy while preparing for larger-scale deployments. Gartner also highlights the importance of building a culture of data literacy within manufacturing organizations, ensuring that teams understand the benefits and potential challenges of IIoT.

Integrating MOM and MES for Efficiency

For example, a metal-forming company recently integrated MES into its MOM system, allowing real-time monitoring of machine performance and optimizing production cycles. According to a recent report by DELMIAWorks, the integration of MES into MOM boosted throughput by 20% and reduced scrap rates by 15%. DELMIAWorks VP Michael Walsh commented, “The integration of MOM and MES creates a seamless digital thread across operations, enabling manufacturers to make fast, data-driven decisions that drive productivity.”

“Digital twins allow manufacturers to anticipate issues before they occur, creating a risk-free environment for testing process changes,” remarked Roland Weber, a leading IIoT consultant, at a recent industry conference. The combination of AI and digital twins is transforming how manufacturers approach efficiency, innovation, and productivity.

Overcoming IIoT Implementation Challenges

In the rapidly evolving manufacturing landscape, operational efficiency has become the cornerstone of competitive advantage. With the Industrial Internet of Things (IIoT) and connected applications, manufacturers are leveraging data to streamline operations, enhance productivity, and reduce costs significantly. In today’s digital era, optimizing production processes using real-time data analytics isn’t just an option—it’s essential.

IIoT also plays a pivotal role in automating manufacturing processes, reducing human error, and increasing production speed and accuracy. Sustainable resource utilization through IIoT allows manufacturers to minimize waste, lower costs, and improve operational efficiencies. With enhanced visibility across the supply chain, manufacturers can coordinate activities seamlessly, ensuring that production schedules align with customer demands.

Future of IIoT: Artificial Intelligence and Digital Twins

Looking ahead, the future of IIoT in manufacturing will be shaped by artificial intelligence (AI) and digital twins—digital replicas of physical assets. Integrating AI with IIoT systems provides deeper insights and predictive capabilities, allowing manufacturers to simulate and optimize production processes in real-time. According to IDC, the market for simulation digital twins is projected to reach 9 billion by 2034, underscoring their significance in the industrial sector.

For example, a large-scale food processing company recently used IIoT sensors to monitor its refrigeration units. By analyzing sensor data in real time, the company identified early signs of equipment wear and adjusted maintenance schedules accordingly. Gartner’s research in 2023 highlighted that this proactive approach resulted in a 25% reduction in maintenance costs and a 35% decrease in unplanned downtime. Gartner’s report also noted that predictive maintenance is now essential for companies aiming to achieve zero-downtime production—a goal once seen as unattainable.

Traditional maintenance approaches often rely on fixed schedules, which can lead to unnecessary downtime or unexpected failures. IIoT facilitates predictive maintenance by continuously monitoring equipment conditions and performance, allowing manufacturers to address potential issues proactively. Sensors track parameters such as vibrations and temperature fluctuations, signaling anomalies that may indicate upcoming failures. This preventive strategy reduces maintenance costs, prolongs machinery life, and minimizes downtime.

The convergence of IIoT and connected applications is reshaping the manufacturing landscape, enabling manufacturers to maximize operational efficiency, enhance product quality, and improve supply chain transparency. By leveraging real-time data, predictive analytics, and automation, manufacturers can meet the challenges of modern production environments while achieving cost savings and reducing waste. As the industry continues to embrace IIoT, manufacturers that adapt will position themselves as leaders in the era of smart manufacturing, driving innovation and operational excellence.